Centrifugal Pump

Defination

A machine for moving a liquid, such as water, by accelerating it radially outward in an impeller to a surrounding volute casing.

A machine for moving a liquid, such as water, by accelerating it radially outward in an impeller to a surrounding volute casing.

A Centrifugal pump have a high-speed rotating impeller whose blades throw the water outwards.

Energy usage

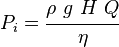

The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. The power required to drive a pump (Pi), is defined simply using SI units by

where:

- Pi is the input power required (W)

- ρ is the fluid density (kg/m3)

- g is the standard acceleration of gravity (9.80665 m/s2)

- H is the energy Head added to the flow (m)

- Q is the flow rate (m3/s)

- η is the efficiency of the pump plant as a decimal

Pump Efficiency

Pump efficiency, η (%) is a measure of the efficiency with wich the pump transfers useful work to the fluid.

η = Pin/Pout (2)

where

η = efficiency (%)

Pin = power input

Pout = power output

Different types of pump head

- Total Static Head - Total head when the pump is not running

- Total Dynamic Head (Total System Head) - Total head when the pump is running

- Static Suction Head - Head on the suction side, with pump off, if the head is higher than the pump impeller

- Static Suction Lift - Head on the suction side, with pump off, if the head is lower than the pump impeller

- Static Discharge Head - Head on discharge side of pump with the pump off

- Dynamic Suction Head/Lift - Head on suction side of pump with pump on

- Dynamic Discharge Head - Head on discharge side of pump with pump on

Problems of centrifugal pumps

- Cavitation—the NPSH of the system is too low for the selected pump

- Wear of the Impeller—can be worsened by suspended solids

- Corrosion inside the pump- caused by the fluid properties

- Overheating due to low flow

- Leakage along rotating shaft

- Lack of prime—centrifugal pumps must be filled (with the fluid to be pumped) in order to operate

- Surge

Fluid sucked trough impeller eye and discharge @ 90 degree angle

ReplyDeleteCentrifugal pumps, are a sub-class of dynamic axisymmetric work-absorbing turbo machinery. Centrifugal pumps are used to transport liquids/fluids by the conversion of the rotational kinetic energy to the hydro dynamics energy of the liquid flow.

ReplyDeletethanks a lot for sharing

hey nice information for us,Buy Malhar Centrifugal Pump. Get best and cheap prices from Centrifugal Pump Manufacturers on SS Centrifugal Pump with installation guide of Centrifugal Pumps in India.

ReplyDeleteCentrifugal Pump

Hi,

ReplyDeleteYou have really done the great job,wonderful article with informative stuff,i loves to follow your blog.

For complete details please visit centrifugal pumps

Thank you for posting this impotant post, keep posting like this kind of content. Other than If you are looking for Centrifugal Pump Manufacturers, Vikas Pumps is one of the top leading industry. They are best in supplying all types of Water Treatment Plant such as:

ReplyDeleteSewage Treatment Plant Manufacturers

Slat Conveyor Manufacturers

STP Plant Manufacturers

Vikas Pump is one of the trusted Centrifugal Pump Manufacturers In India. We deal in different types of Industrial Pumps as per industrial needs like - STP Plant, Sewage Treatment Plant,

ReplyDeleteSlat Conveyor

Hey , your blog is very excellent and Amazing. and in your post very interesting information. Thank you for shearing and providing us. Submersible Pumps manufacturer in India

ReplyDeleteHello sir good job your blog is very Amazing and incredible. your post is most informative. thank you for posting this information. please keep shearing more content. Submersible Pumps manufacturers

ReplyDelete